In today’s rapid development of the Internet of Things and intelligent hardware, efficient and reliable motor drive technology has become the core requirement of robots, smart toys and consumer electronics. The SSP2617 single-channel H-bridge driver chip launched by Shanghai Siproin Microelectronics is redefining the performance standard of low-voltage motion control scenarios with its excellent power handling capabilities, flexible PWM control, and multiple protection mechanisms.

- Chip parameter information:

ESOP8 package

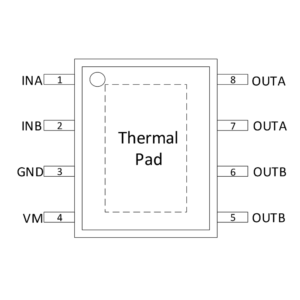

- Pin description

| Pin | Name | Attribute | Function description |

| 1 | WHEN | I | Input INA |

| 2 | INB | I | Input INB |

| 3 | GND | G | Ground |

| 4 | VM | P | H-bridge power supply, connecting 10uF or greater capacitors between VM and GND |

| 5 | OUTB | Or | Output OUTB |

| 6 | OUTB | Or | Output OUTB |

| 7 | OUTA | Or | Output OUTA, 0.1uF connection between OUTA and OUTB |

| 8 | OUTA | Or | Output OUTA, 0.1uF connection between OUTA and OUTB |

| Thermal Pad | G | ground, which is connected to the ground plane of the PCB to ensure proper operation | |

一、 Core advantages: double breakthrough in performance and safety

High-efficiency power output

SSP2617 supports 3.0A continuous current and 5.0A peak current output, with an operating voltage range of 3V to 25V, which can be adapted to a variety of battery-powered scenarios. Its H-bridge adopts a low on-resistance design (RDS(ON) typical value of 0.15Ω), which significantly reduces power consumption and improves energy efficiency, especially suitable for cleaning robots or remote-controlled toys that need to run for a long time.

Control Interface

Through PWM signal input (INA/INB pin), users can accurately control the motor’s forward rotation, reverse, braking, and stop modes to meet the needs of complex motion logic. For example, smart sweepers can adjust the sweeping wheel speed through PWM, while remote-controlled vehicles can achieve smooth direction switching.

Multiple protection mechanisms

- Over-current protection (OCP): Automatically triggers protection when the current exceeds 5.0A to avoid chip damage.

- Over-temperature protection (OTP): Automatically shuts off when the junction temperature reaches 180°C, and recovers after cooling to 120°C to ensure reliability in high-temperature environments.

二、Application: from toys to industry

Smart toys

Remote-controlled cars, drones, and other products can extend battery life and simplify PCB layout with the help of SSP2617’s compact package (ESOP8) and low standby current (10μA).

Service robot

Its high current output ability can drive the roller brush or servo motor of the cleaning robot, combined with PWM to achieve dynamic speed regulation and improve cleaning efficiency.

Industrial Equipment

In automated production lines, SSP2617 brake mode can quickly stop the conveyor motor and reduce mechanical wear, while the industrial-grade temperature range (-40°C~85°C) ensures stability in harsh environments.

Energy meter

With its efficient power output and multiple protection mechanisms, SSP2617 single-channel H-bridge driver chip is an ideal choice for driving magnetic holding relays, helping the meter industry achieve more stable and energy-efficient operation. Its wide voltage range of 3V~25V is suitable for a variety of meter power supply solutions.

三、Design support: simplify development and accelerate mass production

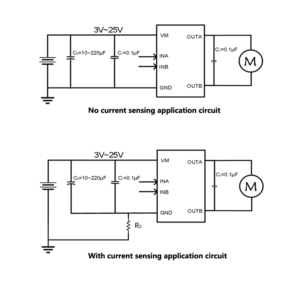

Streamlined peripheral circuitry

The chip has a built-in power management unit, which only requires an external 10μF VM filter capacitor and a 0.1μF motor-end capacitor to operate stably, greatly reducing BOM costs. Typical application diagrams are as follows:

Current Sensing Extension

Developers can monitor the motor current in real time by detecting the resistor (RS) in series in the ground path to realize load diagnosis or fault warning, which is suitable for industrial equipment with high reliability requirements.

- Typical Applications

- Conclusion

With “high performance, high integration, and high reliability” as the core, SSP2617 provides a very cost-effective solution for the field of motion control. Whether it is a start-up team or a large-scale enterprise, its flexible design and technical support from Siproin Microelectronics can quickly achieve product iteration.

_画板-1@2x.png)